CAINÉIL CAIGHDEÁNACH EORPACH UPN (UNP) U

Anbhíoma UPN, a sheasann do chainéil flanse comhthreomhara cruth "U" le trasghearradh cruth "N" nó "I", is cineál bíoma cruach struchtúrach é. Úsáidtear go coitianta é in iarratais tógála agus tionsclaíocha chun tacaíocht agus cobhsaíocht a sholáthar i struchtúir éagsúla. Ceadaíonn dearadh an bhíoma UPN dáileadh meáchain éifeachtach, rud a fhágann go bhfuil sé oiriúnach chun ualaí troma a iompar agus chun fórsaí lúbtha agus casta a sheasamh. Tá na bíomaí seo ar fáil i méideanna agus i dtoisí éagsúla chun freastal ar riachtanais struchtúracha éagsúla. Úsáidtear bíomaí UPN go forleathan i dtógáil foirgneamh, droichid, agus tionscadail bhonneagair eile mar gheall ar a neart agus a solúbthacht.

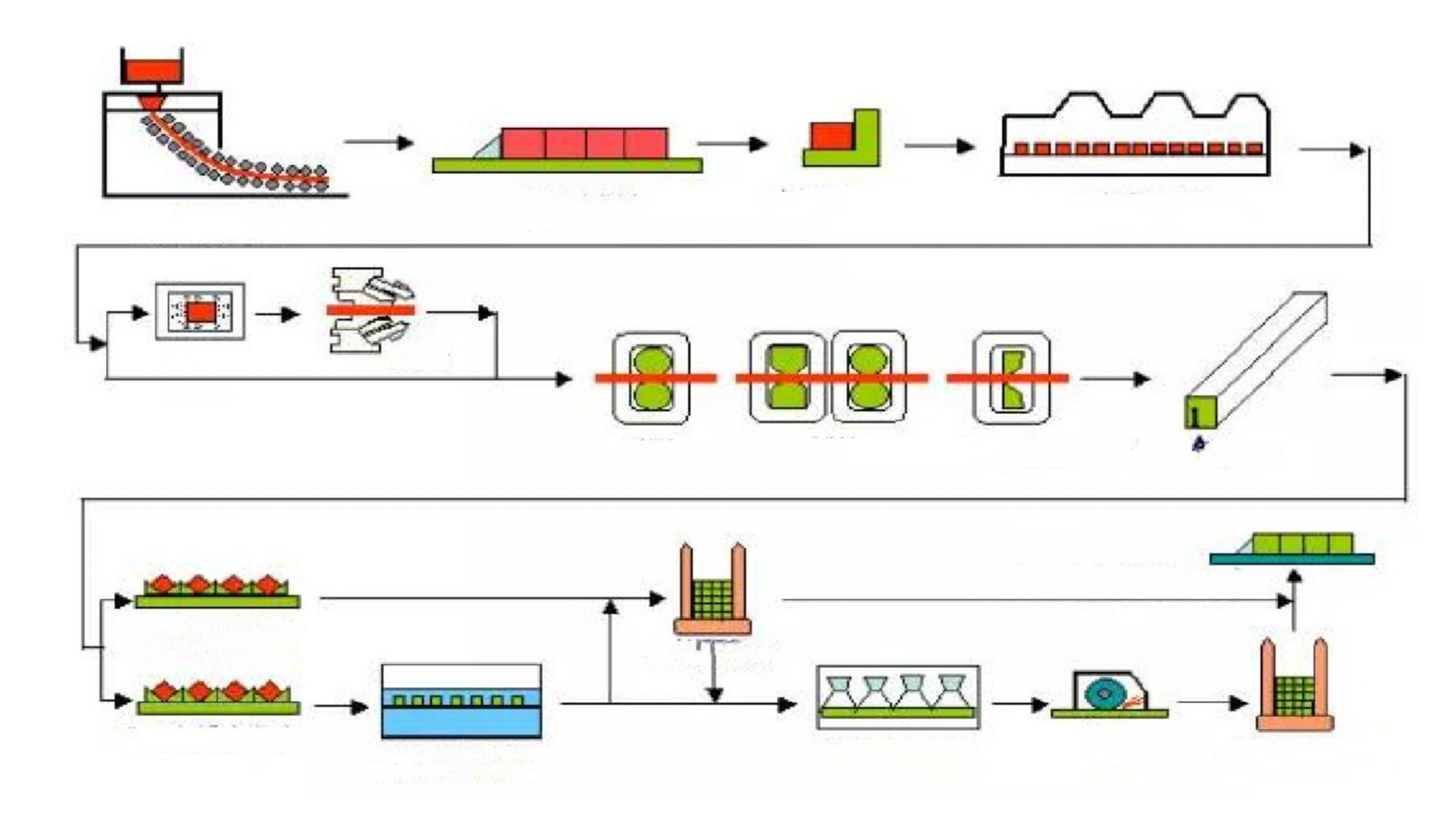

PRÓISEAS TÁIRGITHE TÁIRGE

Bhíoma Uilíochpróiseas táirgthe

1. Ullmhú amhábhar

Is iad na príomh-amhábhair cruach cainéil ná méine iarainn, aolchloch, gual agus ocsaigin. Ní mór na hamhábhair seo a ullmhú roimh an táirgeadh chun leanúnachas agus éifeachtúlacht an phróisis táirgthe a chinntiú.

2. Leá

Leáitear na hamhábhair i bhfoirnéis phléasctha agus déantar iarann leáite díobh. Tar éis don iarann leáite dul faoi chóireáil bhainte slaig, bogtar chuig tiontaire nó foirnéis leictreach é le haghaidh scagtha agus measctha. Trí pharaiméadair amhail toirt doirteadh agus sreabhadh ocsaigine a rialú, déantar na comhpháirteanna san iarann leáite a choigeartú go dtí an cóimheas cuí chun ullmhú don chéad chéim eile den rolladh.

3. Rolladh

Tar éis leá, sreabhann an t-iarann leáite ó bharr go bun sa mheaisín réitigh leanúnaigh chun billet ardteochta a fhoirmiú. Téann an billet faoi shraith oibríochtaí rollta sa mhuileann rollta agus ar deireadh éiríonn sé ina chruach chainéil le sonraíochtaí agus toisí. Déantar uisciú agus fuarú go leanúnach le linn rollta chun teocht na cruach a rialú agus cáilíocht an táirge a chinntiú.

4. Gearradh

Caithfear an cruach chainéil a tháirgtear a ghearradh agus a dheighilt de réir riachtanais an chustaiméara. Tá modhanna gearrtha éagsúla ann, amhail táthú, sábhadh agus gearradh lasrach, agus is minice a úsáidtear teicneolaíocht gearrtha lasrach ina measc. Déantar iniúchadh arís ar an cruach chainéil gearrtha lena chinntiú go gcomhlíonann cáilíocht gach cuid den chruach na ceanglais.

5. Tástáil

Is é an chéim dheireanach ná tástálacha éagsúla a dhéanamh ar na táirgí cruach cainéil. Lena n-áirítear tástáil ar thoisí, meáchan, airíonna meicniúla, comhdhéanamh ceimiceach, srl. Ní féidir ach le táirgí cruach cainéil a ritheann an cigireacht dul isteach sa mhargadh.

Go ginearálta, is slabhra próisis chasta é próiseas táirgthe cruach cainéil a éilíonn rialú beacht ag il-naisc chun cáilíocht agus feidhmíocht táirge idéalach a bhaint amach. Le dul chun cinn na teicneolaíochta agus feabhsú próiseas, leanfar de phróiseas táirgthe cruach cainéil a bharrfheabhsú chun táirgí agus seirbhísí níos fearr a sholáthar do chustaiméirí.

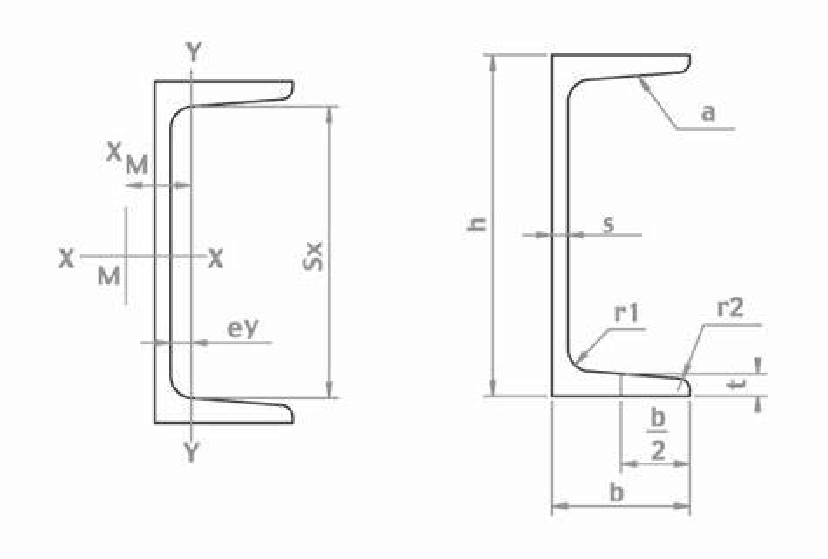

MÉID AN TÁIRGE

| UPN TOIS BARRA CAINÉIL CHAIGHDEÁNACH EORPACH: DIN 1026-1:2000 GRÁD CRUACH: EN10025 S235JR | |||||

| MÉID | U(mm) | B(mm) | T1(mm) | T2(mm) | KG/M |

| UPN 140 | 140 | 60 | 7.0 | 10.0 | 16.00 |

| UPD 160 | 160 | 65 | 7.5 | 10.5 | 18.80 |

| UPN 180 | 180 | 70 | 8.0 | 11.0 | 22.0 |

| UPN 200 | 200 | 75 | 8.5 | 11.5 | 25.3 |

Grád:

S235JR, S275JR, S355J2, srl.

Méid: UPN 80, UPN 100, UPN 120, UPN 140.UPN160,

UPN 180, UPN 200, UPN 220, UPN 240, UPN 260.

UPN 280.UPN 300.UPN320,

UPN 350.UPN 380.UPN 400

Caighdeán: GA 10025-2/GA 10025-3

GNÉITHE

1. Saintréithe cruach cainéil

1. Éadrom: Tá cruach cainéil sách éadrom agus éasca le próiseáil agus le suiteáil.

2. Neart ard: Is féidir le cruth trasghearrthach cruach cainéil a neart agus a dhianacht a fheabhsú, agus is féidir leis ualaí agus fórsaí áirithe a sheasamh.

3. Friotaíocht creimeadh: Tá dromchla cruach an chainéil cóireáilte go speisialta chun creimeadh agus ocsaídiú a chosc go héifeachtach.

4. Inoiriúnaitheacht leathan: Mar gheall ar a airíonna fisiceacha níos fearr, is féidir cruach cainéil a úsáid go forleathan i réimsí éagsúla amhail tógáil, miotalóireacht, agus tógáil long.

IARRATAS

Bhíoma UPN H, a úsáidtear go forleathan san earnáil tógála, tá go leor feidhmeanna acu. Is minic a úsáidtear iad i bhfrámaí foirgneamh, chomh maith le struchtúir tacaíochta do dhroichid, áiseanna tionsclaíocha, agus cineálacha éagsúla innealra. Ina theannta sin, úsáidtear bíomaí UPN go coitianta i dtógáil ardán, idirmheánacha, agus struchtúir ardaithe eile, chomh maith le cruthú creatlach do chórais iompair agus tacaí trealaimh. Tá na bíomaí ildánacha seo riachtanach freisin i bhforbairt aghaidheanna foirgneamh agus córais díonta. Tríd is tríd, is comhpháirteanna ríthábhachtacha iad bíomaí UPN i raon leathan feidhmeanna tógála agus innealtóireachta.

PACÁISTÍOCHT AGUS LOINGSEOIREACHT

1. Fillteán: Filltear na foircinn uachtaracha agus íochtaracha agus lár an chruach chainéil le chanbhás, bileog plaisteach agus ábhair eile, agus baintear pacáistiú amach trí phacáistiú. Tá an modh pacáistithe seo oiriúnach do phíosa aonair nó méid beag cruach chainéil chun scríobtha, damáiste agus cásanna eile a chosc.

2. Pacáistiú pailléid: Cuir an cruach chainéil go cothrom ar an pailléad, agus socraigh é le téip strapála nó scannán plaisteach, rud a laghdóidh ualach oibre an iompair agus a éascaíonn láimhseáil. Tá an modh pacáistithe seo oiriúnach do phacáistiú cainníochtaí móra cruach chainéil.

3. Pacáistiú iarainn: Cuir an cruach chainéil isteach sa bhosca iarainn, agus ansin séalaigh é le hiarann, agus socraigh é le téip cheangailteach nó scannán plaisteach. Is féidir leis an mbealach seo an cruach chainéil a chosaint níos fearr agus tá sé oiriúnach le haghaidh stóráil fhadtéarmach na cruach chainéil.

NEART NA CUIDEACHTA

Déanta sa tSín, seirbhís den chéad scoth, cáilíocht cheannródaíoch, clú agus cáil dhomhanda

1. Éifeacht scála: Tá slabhra soláthair mór agus monarcha cruach mhór ag ár gcuideachta, rud a bhaineann éifeachtaí scála amach in iompar agus soláthar, agus a éiríonn ina cuideachta cruach a chomhtháthaíonn táirgeadh agus seirbhísí.

2. Éagsúlacht táirgí: Éagsúlacht táirgí, is féidir aon chruach is mian leat a cheannach uainn, ag gabháil go príomha i struchtúir chruach, ráillí cruach, carnán bileog cruach, lúibíní fótavoltach, cruach cainéil, cornaí cruach sileacain agus táirgí eile, rud a fhágann go bhfuil sé níos solúbtha Roghnaigh an cineál táirge atá uait chun freastal ar riachtanais éagsúla.

3. Soláthar cobhsaí: Is féidir le líne táirgthe agus slabhra soláthair níos cobhsaí soláthar níos iontaofa a sholáthar. Tá sé seo thar a bheith tábhachtach do cheannaitheoirí a bhfuil cainníochtaí móra cruach ag teastáil uathu.

4. Tionchar branda: Tionchar branda níos airde agus margadh níos mó a bheith agat

5. Seirbhís: Cuideachta mhór cruach a chomhtháthaíonn saincheapadh, iompar agus táirgeadh

6. Iomaíochas praghais: praghas réasúnta

*Seol an ríomhphost chuig[ríomhphost cosanta]chun luachan a fháil do do thionscadail

CUAIRT CUSTAIMÉIRÍ

Ceisteanna Coitianta

1. Conas is féidir liom luachan a fháil uait?

Is féidir leat teachtaireacht a fhágáil chugainn, agus freagróimid gach teachtaireacht in am.

2. An seachadfaidh tú na hearraí in am?

Sea, geallaimid táirgí den chaighdeán is fearr a sholáthar agus seachadadh in am. Is í an macántacht bunphrionsabal ár gcuideachta.

3. An féidir liom samplaí a fháil roimh ordú?

Sea, ar ndóigh. De ghnáth bíonn ár samplaí saor in aisce, is féidir linn iad a tháirgeadh de réir do shamplaí nó líníochtaí teicniúla.

4. Cad iad do théarmaí íocaíochta?

Is é an téarma íocaíochta is gnách atá againn ná éarlais 30%, agus an chuid eile i gcoinne B/L. EXW, FOB, CFR, CIF.

5. An nglacann tú leis an iniúchadh tríú páirtí?

Glacaimid leis go hiomlán.

6. Conas a mhuinínimid as do chuideachta?

Speisialtóireacht againn i ngnó cruach le blianta mar sholáthraí órga, tá ár gceanncheathrú lonnaithe i gCúige Tianjin, fáilte romhat imscrúdú a dhéanamh ar aon bhealach, ar gach uile bhealach.